How Perfume Oils Are Made: From Botanicals to Bottle

How Perfume Oils Are Made: From Botanicals to Bottle

Perfume oils, the essence of fragrances, are crafted through a meticulous process that transforms natural botanicals into the captivating scents we cherish. This journey involves several key stages:

1. Sourcing Quality Botanicals

The foundation of any exceptional perfume oil lies in the quality of its raw materials. Botanicals such as roses, lavender, jasmine, and citrus fruits are harvested for their aromatic properties. For instance, obtaining rose oil requires the extraction of essence from approximately 660 roses to produce just 15 milliliters of oil.

2. Extraction Methods

Once harvested, the aromatic compounds are extracted using various methods:

Steam Distillation: Commonly used for flowers like lavender and rose, this method involves passing steam through plant material to vaporize the volatile compounds, which are then condensed back into liquid form.

Solvent Extraction: Suitable for delicate flowers, this technique uses solvents to dissolve the essential oils, which are then separated and purified.

Cold Pressing: Typically applied to citrus fruits, this method mechanically presses the peel to release the essential oils.

3. Blending and Compounding

After extraction, perfumers blend various essential oils to create harmonious scent profiles. This stage involves combining top, middle, and base notes to achieve a balanced fragrance. The blending process is both an art and a science, requiring expertise to ensure the longevity and appeal of the perfume.

4. Maturation and Aging

The blended perfume oil undergoes a maturation period, allowing the components to meld and develop depth. This aging process can last from several weeks to months, enhancing the complexity and richness of the fragrance.

5. Dilution and Filtration

To prepare the perfume oil for consumer use, it is diluted with alcohol or carrier oils, depending on the desired product type. For example, Eau de Parfum typically contains 15–20% concentrate in alcohol. After dilution, the mixture is filtered to remove impurities, ensuring clarity and purity. ((https://www.leuxscent.com/from-raw-materials-to-finished-products-the-entire-process-of-flavor-production.html))

6. Bottling and Packaging

The final perfume oil is carefully bottled, often in amber glass containers to protect the fragrance from light degradation. Packaging is designed not only for aesthetic appeal but also to preserve the integrity of the scent.

7. Quality Control and Testing

Throughout the production process, rigorous quality control measures are implemented. This includes olfactory evaluations, chemical analyses, and safety compliance checks to ensure the final product meets industry standards and consumer expectations.

8. Distribution and Delivery

Once the perfume oil has passed all quality checks, it is ready for distribution. Efficient logistics ensure that the product reaches consumers in optimal condition, maintaining the fragrance's quality and appeal.

Frequently Asked Questions (FAQ)

Q1: How long does it take to create a perfume oil?

A1: The creation of a perfume oil can take anywhere from several weeks to several months, depending on the complexity of the fragrance and the aging process required.

Q2: What are the main extraction methods for perfume oils?

A2: The primary extraction methods include steam distillation, solvent extraction, and cold pressing, each suited to different types of botanicals.

Q3: Why is aging important in perfume oil production?

A3: Aging allows the various components of the perfume to blend and develop depth, resulting in a more complex and harmonious fragrance.

Q4: How is the quality of perfume oils ensured?

A4: Quality is ensured through rigorous testing, including olfactory evaluations, chemical analyses, and adherence to safety standards.

Q5: What is the role of dilution in perfume oil production?

A5: Dilution adjusts the concentration of the perfume oil, making it suitable for different applications such as Eau de Parfum or Eau de Toilette.

Contact Us

For more information on our perfume oil products or to explore our range, please visit our (#) or contact our customer service team.

About LEUXSCENT

LEUXSCENT is a global fragrance and flavor manufacturer founded in 2003. As one of China's top ten enterprises in the fragrance industry, we integrate independent R&D, production, and global operations. Our two production bases in Guangzhou and Qingyuan, Guangdong Province, serve as hubs for innovation and quality manufacturing.

With 17 invention patents and over 10 national, provincial, and municipal innovation projects, we've built robust R&D capabilities, including the Guangzhou Municipal Enterprise Technology Center, Guangdong Engineering Technology Research Center, and an upcoming postdoctoral workshop.

At LEUXSCENT, we offer complete OEM/ODM solutions for fragrance and personal care products, helping brands launch or scale with tailored, compliant, and market-driven formulas. Our expertise spans food, seasonings, daily chemicals, and tobacco flavors, delivering high-quality, custom-crafted sensory experiences to clients worldwide.

Our Main Products and Core Competencies

Fragrance Oils: We offer a diverse range of fragrance oils, including perfume oils, essential oils, aroma oils, and flavor fragrances, catering to various applications in the fragrance industry.

Core Competencies: Our strengths lie in our independent R&D capabilities, quality manufacturing processes, and a deep understanding of market trends, enabling us to deliver innovative and high-quality products to our clients.

SEO Optimization

Meta Title: How Perfume Oils Are Made: From Botanicals to Bottle

Meta Description: Discover the intricate process of perfume oil production, from sourcing botanicals to the final bottled fragrance.

Keywords: perfume oil, fragrance oil production, perfume manufacturing process, essential oils, fragrance extraction methods

URL Alias: how-perfume-oils-are-made-from-botanicals-to-bottle

Note: The information provided is based on general industry knowledge and may vary depending on specific production methods and practices.

Top 10 home fragrance oil Manufacturers and Supplier Brands

Wholesale jasmine fragrance oil manufacturer and supplier in 2026

Best essential oil manufacturers and supplier brands

Fragrance Oil Concentrations: Perfume Oil Strength Guide

OEM Service

What are EXW, FOB, CFR, and CIF? Which should I choose?

Can I send you a sample to recreate the scent?

Wholesale

Does the factory support on-site audits and third-party inspections?

Yes, Leuxscent welcomes client audits and supports third-party inspections.

Private Label Production

Can I request branded samples?

Yes. We support multiple sample iterations with full branding for client review.

FAQs

Where are your production bases located?

We have two production bases in Guangzhou and Qingyuan, Guangdong Province, both following strict GMP standards.

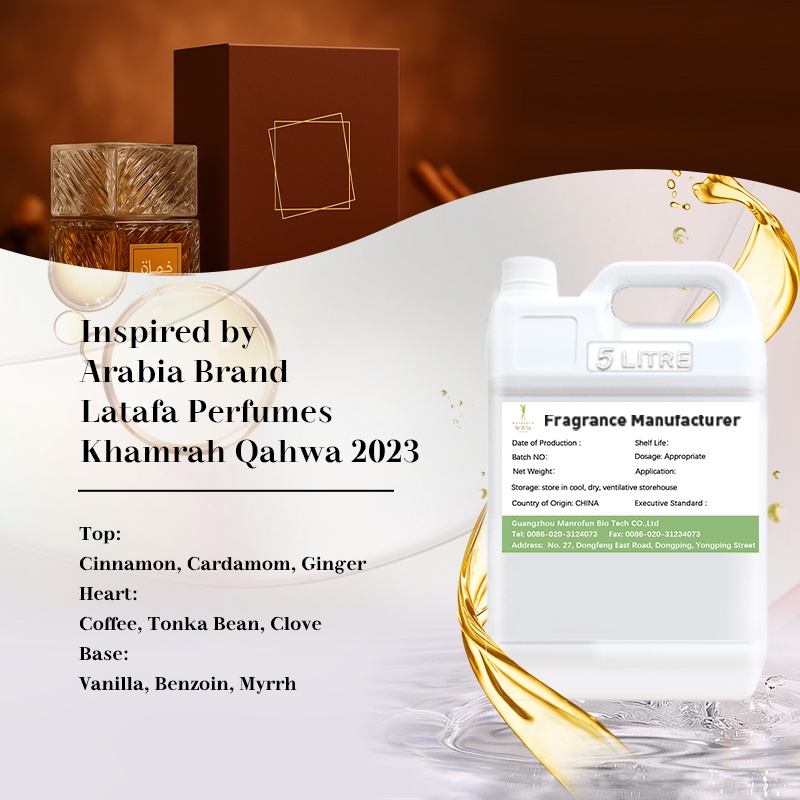

Khamrah Qahwa Type Fragrance Oil | Spiced Coffee Perfume Oil

Khamrah Qahwa Type Fragrance Oil | Spiced Coffee Perfume Oil

Inspired Designer Perfume by Arabian Asad Bourbon Fragrance Oil

Inspired Designer Perfume by Arabian Asad Bourbon Fragrance Oil

Perfume Fragrance Oil OEM Private Label Refill Program IFRA Compliant Manufacturer Supply Designer Perfume Oil

Perfume Fragrance Oil OEM Private Label Refill Program IFRA Compliant Manufacturer Supply Designer Perfume Oil

Scan QR Code

Scan QR Code

Facebook

Instagram

LinkedIn

YouTube

Pinterest